Abigail D. Ross1,2, Isaac O’Rourke1,2

1 Montana Space Grant Consortium Balloon Outreach, Research, Exploration and Landscape, Imaging, System Program

2 Montana State University, Culbertson Hall, 100, Bozeman, MT 59717, United States

Abstract

Alongside 53 teams in the Nationwide Eclipse Ballooning Project (NEBP), the Montana Space Grant Consortium (MSGC) Balloon Outreach, Research, Exploration and Landscape Imaging System (BOREALIS) Program aimed to livestream a solar eclipse to the NASA website via a high-altitude weather balloon and collect data on atmospheric phenomena. The project required a weather balloon capable of reaching neutral buoyancy for optimal data collection, connectivity and viewership. However, the cost of professionally manufactured balloons and the labor-intensive nature of manual production, coupled with weather constraints, necessitated an innovative, cost-effective solution. The goal was to design a system that organizations with varying resources and expertise could reproduce and operate.

In response to these concerns, we designed, fabricated and tested a vent attachment for latex balloons to enable controlled helium release and achieve neutral buoyancy. The predominantly 3D-printed vent reduced production costs and improved reproducibility, with the entire system manufacturable in under nine hours. Mechanically, it featured a plumbing fixture that acted as a plunger to release helium as needed. For strength, Polyethylene Terephthalate Glycol (PETG) was chosen over Polylactic Acid (PLA) filament, and a clear coat lacquer ensured airtightness.

The vent system integrates a cutdown module, custom vent board, servo motor, Hall effect sensor and battery, all housed for easy access. Additionally, a new parachute packing method based on reserve parachutes used by paragliders was developed. While minor modifications are still required, the vent has proven effective in maintaining altitude above 80,000 feet, meeting project objectives.

Introduction

Foundational overview of achieving neutral buoyancy with weather balloons

For many years, organizations and institutions have been exploring new avenues for high-altitude weather balloons to achieve neutral buoyancy during flight, aiming to extend flight duration and enhance data collection (Basta et al. 2014). To broaden engagement in scientific ballooning, the Nationwide Eclipse Ballooning Project (NEBP) developed a NASA-like mission endeavor to live- stream the solar eclipses to the NASA website from a high-altitude balloon and collect data to study the eclipse’s impact on atmospheric phenomena (Eclipse.montana.edu, n.d.).

The critical data-gathering payloads—Iridium (which communicates between the balloon payload, the groundstation and the Iridium satellite network), RFD 900 radio modem and the Raspberry Pi Camera (Raspberry Pi Holdings, United Kingdom)—require precise altitude control and stability to ensure ideal payload operation. This stability is crucial for accurate data collection, reliable connectivity and effective viewer engagement. Historically, zero-pressure and super-pressure balloons have been the primary methods used to float a balloon (Adkins 2015). A zero-pressure balloon operates as an open system, releasing excess lift gas through vents to continuously equalize with the dynamic atmospheric pressure. In contrast, a super-pressure balloon is initially underfilled with lift gas, allowing internal pressure to rise as atmospheric pressure drops. This continues until the balloon achieves neutral buoyancy and eventually ruptures. Both zero-pressure and super-pressure balloons are uncommanded during flight and float duration. However, they are significantly more expensive than latex balloons, which previously could not sustain extended flight durations.

Over a decade ago, efforts began to design and develop a vent attachment for latex balloons to reduce reliance on zero-pressure and super-pressure balloons. Although zero-pressure and super-pressure balloons are designed to reach neutral buoyancy autonomously, both are costly to acquire, labor-intensive to produce and challenging to launch in non-ideal weather conditions. With the creation of the Nationwide Eclipse Ballooning Project (NEBP), the Montana Space Grant Consortium (MSGC) Balloon Outreach, Research, Exploration and Landscape Imaging System (BOREALIS) Program led more than 50 teams nationwide in collaboration through workshops, conferences and coordinated launches. This effort made the development of a vented latex balloon increasingly appealing due to its potential to improve reproducibility and simplify the launch process compared to zero-pressure balloons.

Previous vent designs and key features

Prior to this work, institutions and researchers had been developing a range of vent attachment concepts for latex weather balloons, including autonomous and commanded control strategies, mechanical designs and software systems; however, none had resulted in successful deployment (Flaten et al. 2014). Mechanically, the greatest challenges presented in these vent designs were overall weight and size, sealing, reproducibility, components freezing and accessibility to components during launch operations. These issues led to performance variability and limited success during tests and flights; this often resulted in inconsistent altitude control, premature vent failures and complications during the preparation and launch process. Specifically, this research with the BOREALIS Program identified several key deficiencies in previous designs. These included leaks and insufficient seals in the helium release flap and vent attachment to the balloon neck, servo motors freezing, premature battery failure in extreme temperatures and excessive 3D-printing time requirements.

Outlined objectives

The objective of the research conducted leading up to the annular and solar eclipses in 2023 and 2024, respectively, was to analyze, refine, redesign, streamline, test, support and debug previous vent designs. The new vent design sought to minimize 3D-printing time, ensure component retention and reuse for each flight, resolve all sealing problems, easily display and access all electronics, support reproducibility and allow future improvements without requiring a complete redesign of existing components.

Methodology and Developments

Design collaboration and focus

The vent attachment design for latex weather balloons was developed in collaboration with previous research efforts from the BOREALIS Program and the Maryland Space Grant Consortium University of Maryland ballooning program. The electronic and software features necessary for floating latex weather balloons had already been well-established, so the mechanical designs and developments were directed at seamless integration with the existing electronic systems.

Mechanical evolution and sealing solutions

The mechanical foundation of the vent was centered on a plastic plumbing fixture functioning as a plunger, adapted from an earlier BOREALIS design. However, modifications were necessary to improve the fixture’s sealing capacity and integrate it with the Hall effect feature of the vent board designed by BOREALIS researchers. The sourced plumbing fixture was not designed to prevent gases from escaping. As a result, we focused on creating an effective seal that could both trap the helium gas in the balloon while the vent was closed and still allow enough helium to escape when the vent was open to efficiently achieve neutral buoyancy.

The first design rendition to establish an airtight seal utilized a rubber gasket attached to the top face of the plunger that moved vertically and made contact with the flat, stationary housing of the plumbing fixture. The rubber gasket extended beyond the gaping seam between the surrounding housing and the vertically moving shaft. Additional development to the plumbing fixture included exploring 2 variations of O-ring placements. Initially, we inserted an O-ring along the inner lip where the shaft and housing met. However, that design was quickly rejected due to difficulty machining the inner surface and variability in the plumbing fixtures. Instead, the gasket was used, and the top of the surrounding housing was machined on the lathe to create a groove matching the width and diameter of the O-ring used. This allowed the O-ring to be inlaid in the surface, creating a rubber-on-rubber seal with the gasket. Further advancing the plumbing fixture, the ball at the end of the vertically moving shaft was machined so a magnet could be securely fastened to the tip. This allowed the plunger and magnet to be easily integrated with the Hall effect sensor on the vent board, which indicates whether the vent was opened or closed.

Material selection

The vent design process incorporated iterative improvements to address mechanical weaknesses identified in earlier versions. Throughout the engineering design process to develop the vent, both PLA and PETG filaments were tested for each component. Each fabrication iteration included a consistent evaluation of as-printed quality, post-print processing performance, air-tightness and flight durability. A significant challenge occurred during the maiden flight test of the vent system, resulting in the Iridium module and other components being ejected from the payload immediately following flight termination. This complication was traced to the mechanical failure of the 3D-printed PLA housing surrounding the eye bolts, which had served as the primary attachment point for the entire payload.

The abruptness of the flight termination sequence subjected the payload to immense shock forces that exceeded the tensile strength of the thin PLA tabs securing the eye bolts. To mitigate these issues, we implemented a material transition from PLA to PETG for the main vent body, leveraging the superior mechanical strength and durability of PETG under high-stress conditions. Ultimately, PETG was selected for producing every printed component.

Overall, the strength, durability and UV resistance of PETG filament were integral qualities in the performance of PETG in the given setting (Polygenis 2023). Compared to PLA, PETG filament displayed better layer adhesion, thus sealing qualities and structural integrity, as identified by applying soap and water to the surface of the main body to identify leaks. Despite the better layer adhesion of PETG, the fillets around the helium fill valve and fasteners along the base of the main vent body were commonly identified as areas where helium gas would escape. As a result, a layer of adhesive and clear coat lacquer was applied to each main vent body produced to ensure the sealing capabilities of the vent.

Additionally, in response to the mechanical failures of the maiden flight test of the vent system, all load-bearing components of the vent hardware were upgraded to zinc-plated steel to further enhance system durability and withstand the forces experienced during flight termination. These modifications ensured the structural integrity of the vent and payload assembly, addressing the mechanical vulnerabilities observed in earlier iterations.

Electronics integration and accessibility

Directly inspired by the vent designed by the University of Maryland ballooning team, the vent featured an open-concept design for the housing of the electronics. The cutdown module, vent board, servo-motor and battery were all visible, which allowed for easy access to the cable connections and indicator LEDs crucial during pre-flight preparations and test operations. In addition to the accessibility to the electronics, the open-concept design facilitated unobstructed reach to the shaft of the plunger and the location of its seal to allow for rapid pre-flight analysis and adjustments as necessary to ensure proper placement of the plunger and gasket for optimal sealing.

Improving reusability

We conducted extensive research, testing, design and redesign on the Marman band, a clamping mechanism commonly used in aerospace and industrial applications. The preliminary Marman band design featured three separate segments, connected with cable ties and attached to the balloon via a flight line routed through the cutdown module.

As the initial design caused bunching of the latex and leaks around the neck, the engineering design strategies were aimed at testing the inner geometry of the Marman band, the percentage of the balloon neck that the Marman band encompassed and the number of segments utilized to make the component. Furthermore, early renditions of the Marman band required the use of vacuum grease around the neck of the balloon and neck of the vent system. Although the vacuum grease minimized the helium escaping around the attachment between the balloon and vent system, the temperature in the stratosphere caused the vacuum grease to freeze, ultimately interfering with the flight termination mechanisms.

Eventually, a two-segment Marman band featuring a hinge composed of a torsion spring and small steel rod to connect the two segments was identified as the optimal design. Not only did the hinge, specifically the moment arm of the torsion spring, allow for easy reuse of the component, but it also provided ample torque to release the Marman band from the neck of the balloon following cutdown. The internal contour of the Marman band was carefully designed to mirror the exact profile of the vent neck, which adequately secured the balloon to the vent and did not require the use of vacuum grease to minimize leaks. Additionally, the components of the Marman band were connected with a hinge, and a seat-belt attachment was incorporated to fully retain the component following flight termination.

The vent was mindfully constructed with an emphasis on reusability, which is ideal for flight demands, failure analysis and dispositioning the condition of the vent. Integral to the preservation of the vent system was the new method for packing the parachute within the balloon payload. Previous designs did not allow for the vent to fall under the parachute following cutdown and during descent, which was detrimental to payloads and compromised the condition of the vent. As a result, we developed a new parachute packing system, closely following the techniques used to pack a reserve parachute for paragliding and paramotoring. The new parachute packing system was required to be attached to the main vent body in order for the vent to fall under the parachute. Due to the placement of the electronics and minimal external features on the main vent body, the parachute packing system was easily and successfully integrated into the vent design.

Results

After rigorous flight testing and various testing measures conducted on the ground, even the initial rendition of this vent showed promising capabilities, as illustrated in Figure 1, to successfully float a latex weather balloon for the duration of a solar eclipse. As shown in the altitude–time data in Figure 1, the balloon halted its ascent during the maiden test flight, and the pin-state readings confirmed that the vent had opened and closed. This information was communicated from the balloon back to the ground station via the Iridium satellite network.

Figure 1. The altitude, in feet, of the new vent design on its maiden voyage on July 25th, 2023, with respect to Coordinated Universal Time, compiled from the Iridium data collected during flight Schwehr (2024).

Launched at 7:22 AM MDT (13:22 UTC), the vented latex balloon reached 79,547 feet (24246 meters) when the balloon began its float at 8:33 AM MDT (14:33 UTC) (Schwehr 2024). Despite the vent being closed, the balloon steadily dropped nearly 15,000 feet (4572 meters) from the initial time neutral buoyancy was achieved until flight termination at 10:55 AM MDT (16:55 UTC), a descent rate of approximately 105 feet per minute (0.5334 meters per second) (Schwehr 2024).

Also apparent in Figure 1 is the lack of data depicting the balloon descent following flight termination. Unfortunately, the Iridium module and other components were ejected from the payload immediately following flight termination. While the data collected during the flight demonstrated the vent’s effectiveness, challenges with the mechanical durability of the payload attachment system were observed following flight termination. These challenges prompted subsequent design improvements, including material transitions and hardware upgrades, previously detailed.

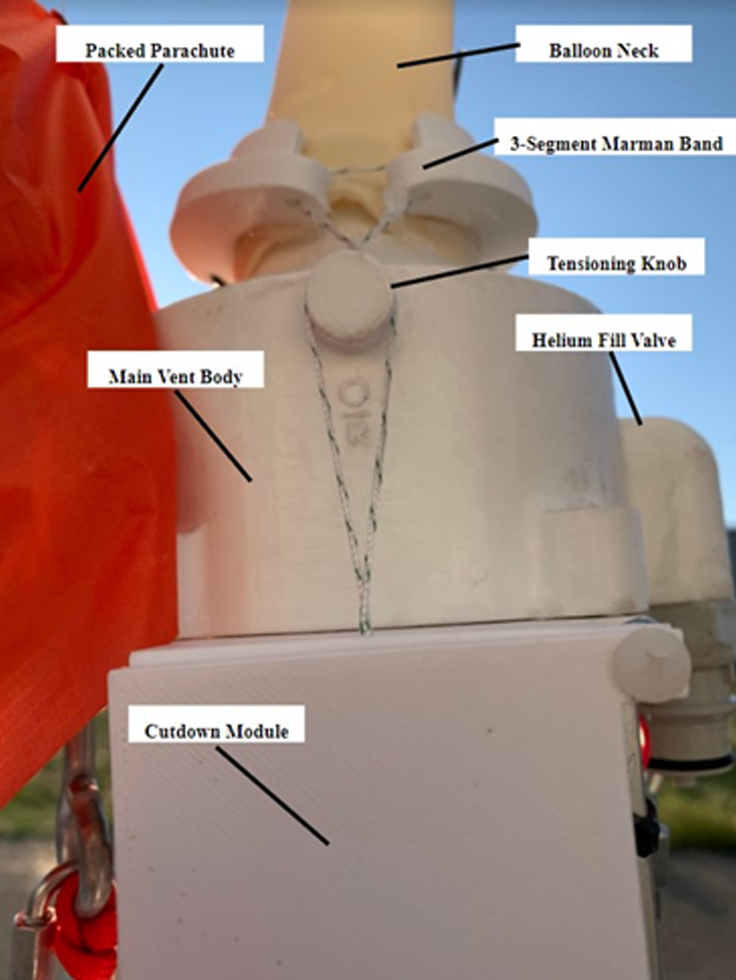

Evidenced by Figure 2, which is an annotated picture of the vent taken after the balloon had been filled and immediately before launch, the Marman band caused bunching around the neck of the balloon allowing helium to escape. Vacuum grease was applied around the neck of the balloon, particularly in the gap between the latex and the vent system, to minimize helium leakage and attempt to salvage the flight. Furthermore, gas was observed to be escaping the seal around the plunger. Both of these observations and supporting flight data prompted the redesign process of the plunger mechanism and Marman band previously described.

Figure 2. An annotated image of the new vent design prior to launch on its maiden voyage, highlighting key components of the system and features contributing to underperformance in preliminary designs

Following the modifications based on the experimentation and engineering design process previously outlined, the final version of the vent was flown for the annular solar eclipse on October 14, 2023 and total solar eclipse on April 8, 2024. Illustrated by Figures 3 and 4 and confirmed by pin states, the vent successfully floated for the duration of each solar eclipse free from any significant leaks.

Launched at 6:38 AM PDT (13:38 UTC) from Winnemucca, Nevada, the vented latex balloon reached its float altitude of 79,856 feet at 7:55 AM PDT (14:55 UTC), eleven minutes before the start of the eclipse at 8:06 AM PDT (Schwehr 2024; Time and Date 2024). Due to the cooling of the atmosphere as the moon traveled in front of the sun, the balloon gradually dropped in altitude until it reached its lowest point of 68,517 feet (20884 meters) during float at 9:43 AM PDT (16:43 UTC) (Schwehr 2024). This occurred only 21 minutes after the maximum totality of the eclipse (Time and Date 2024). Finally, as the atmosphere heated as the moon traversed across the sun, the helium expanded allowing the balloon to regain altitude, ultimately reaching 79,137 feet at 12:01 PM PDT (18:01 UTC) when the flight was terminated (Schwehr 2024).

Figure 3. The altitude, in feet, of the new vent design during the annular solar eclipse in Winnemucca, Nevada on October 14th, 2023, with respect to Coordinated Universal Time, compiled from the Iridium data collected during flight Schwehr (2024).

Figure 4. The altitude, in feet, of the new vent design during the total solar eclipse in Fort Wayne, Indiana on April 8th, 2024, with respect to Coordinated Universal Time, compiled from the Iridium data collected during flight Schwehr (2024).

Following similar flight behavior to the annular eclipse, the vented latex balloon was launched from Fort Wayne, Indiana at 12:55 PM EDT (16:55 UTC) (Schwehr 2024). It reached neutral buoyancy at 2:21 PM EDT (18:21 UTC) at an altitude of 84,754 feet, twenty-eight minutes following the start of the total eclipse (Schwehr 2024; Time and Date 2024). Again, with the cooling of the atmosphere, the balloon slowly descended to 75,850 feet at 3:30 PM EDT (19:30 UTC), only twenty minutes following the maximum totality of the eclipse (Schwehr 2024; Time and Date 2024). After recovering altitude as the atmosphere warmed, the balloon reached 85,965 feet at 4:39 PM EDT (20:39 UTC), when the flight was terminated (Schwehr 2024).

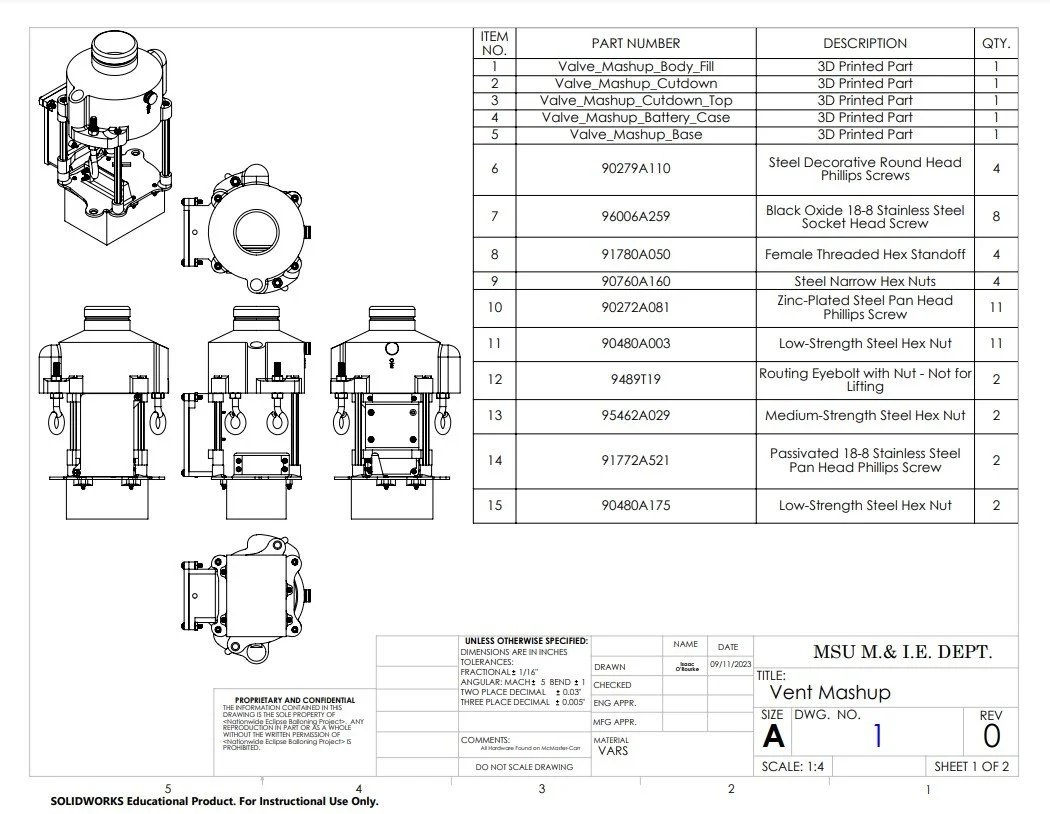

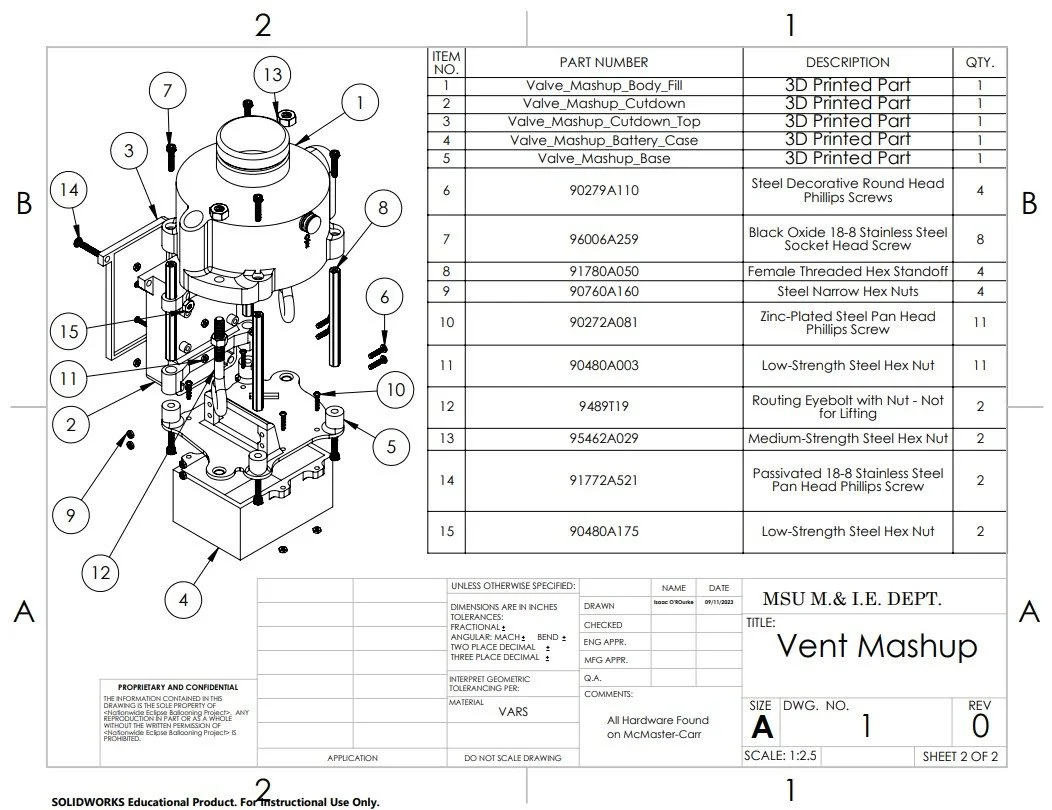

The consistent flight performance during both the annular and total solar eclipses, shown in Figures 3 and 4, demonstrates the reliability of the system. Additionally, the operational progress illustrated in Figure 1 further supports these results. Together, these data confirm that the modifications and final vent design—fully illustrated in the SolidWorks drawings in Figures 5 and 6—were effective in meeting the NEBP objectives established through the engineering design process. During both eclipses, the vent floated successfully, providing the system with stable operation. As a result, the Raspberry Pi Camera produced steady livestream footage, the RFD900 collected high-quality gravity-wave data, and the Insta360 and DSLR cameras captured clear images for post-flight analysis. Furthermore, the ability of the vent to consistently float, even with minor sealing issues in the early development of the system, allowed the aforementioned payloads to be tested in controlled circumstances. Moreover, the vent design withstood the mechanically demanding flight operations as components of the vent, if not the entire system, were reused on additional flight tests. The reusability of the vent components and the reduced manufacturing time of 9 hours, compared to over 36 hours for earlier versions, maximized the amount of testing not only of the vent system but also of the other payload components.

Figure 5. The multi-view SolidWorks drawing and complete bill of materials of the final vent assembly.

Figure 6. The SolidWorks exploded assembly drawing and complete bill of materials of the final vent design.

Discussion and Conclusions

The flight data demonstrate the effectiveness of the new vent design. The system demonstrated consistent performance during both the annular and total solar eclipses, meeting the NEBP objectives and supporting the operation of the other critical payload components. Furthermore, key components improved the ease and efficiency of flight operations. Among other favored improvements, the placement of the magnet at the end of the ball of the plunger mechanism and the open concept electronic housing allowed the magnet location with respect to the Hall effect sensor to be rapidly aligned and adjusted immediately prior to launch. In addition, the Marman band maximized the security of the balloon to the valve while simplifying the process to attach the balloon to the vent and cutdown module. Improvements like these ensured reliable performance during flight operations and streamlined flight preparations.

In addition to the vent design, we created and implemented thorough and in-depth documentation for participating NEBP teams to facilitate access to the design, technical support for use and collaboration with other researchers. The documentation supporting the vent system—including detailed SolidWorks drawings (Figures 5 and 6), a guide for 3D printing the vent components, access to all CAD files and a 35-minute instructional YouTube video—was made easily accessible through the NEBP “Introduction to Scientific Ballooning: NEBP Engineering Track” webpage (Montana.edu 2023). The documentation was created and compiled throughout the engineering design process, which inspired the design decisions to achieve efficacy and efficiency through simplicity. This allowed the vent design and functionality to be easily reproduced and used by ballooning groups with various levels of expertise and resources.

As previously outlined in the objectives and expectations, the final vent design has the capacity to support improvements and additions to accompany advancements in the high-altitude ballooning field. For instance, the effective yet simple and sleek design established by the modularity of the vent, available surface area on the main vent body and versatility of the open- concept electronics housing for additions is conducive for autonomous payload recovery and delivery systems. Specifically, preliminary research and development for an autonomous steerable parachute system, aimed at delivering the payload to a predetermined waypoint, has demonstrated that this vent could be easily adapted, without drastically modifying the main mechanical features, to integrate the airfoil with the already existing parachute packing system and include the control body for the autonomous system with the existing electronic housing.

Looking ahead, further research can be conducted to minimize costs and maximize reproducibility by making the entire vent system 3D-printed, with the exception of load-bearing components such as the eye bolts and aluminum standoffs. In particular, the plastic plumbing fixture, which is used as a plunger, was challenging to source and presented extreme variability between suppliers. Therefore, designing and 3D printing this component could minimize the dependence of organizations and researchers on unreliable and inconsistent suppliers. Measures were already instituted to minimize purchased hardware by redesigning the cutdown module to feature hinges instead of nylon screws and nuts to access and securely fasten the cutdown board.

This project embodies a progression toward increasing access to high-altitude ballooning research by providing a solution that is cost-effective and can be specialized for diverse research and mission requirements.

Acknowledgements

This work was made possible by the generous support of the Montana Space Grant Consortium BOREALIS Program, especially co-flight directors and the mentors of the research discussed, Michael Walach, PhD and Randy Larimer, PE, BOREALIS researchers and contributors and NEBP participants. Additionally, this research was supported by the Montana Space Grant Consortium leadership, Angela Des Jardins, PhD, Meredith Hecker, PhD and Chris Flynn.

References

Adkins, J. (2015) ‘Scientific balloons FAQs’, NASA, available: https://www.nasa.gov/scientificballoons/faqs/ [accessed 18 August 2024].

Basta, T., Miller, S., Trevor, R., Larimer, R. and Knighton, B. (2014) ‘Weather balloon altitude control system’, Montana State University Senior Design Report, available: https://ece.montana.edu/seniordesign/archive/FL14/WeatherBallon/docs/final_report.pdf [accessed 18 August 2024].

Eclipse.montana.edu (n.d.) ‘Eclipse Ballooning Project’, Eclipse Ballooning Project, available: https://eclipse.montana.edu/ [accessed 18 August 2024].

Flaten, J.A., Frick, S., Ngure, A., Weiher, H., Jackson, J. and Hladun, M. (2014) ‘Uplink, downlink, and how not to vent a high-altitude balloon’, 5th Annual Academic High-Altitude Conference, available: https://www.iastatedigitalpress.com/ahac/article/8156/galley/10966/view/ [accessed 18 August 2024].

Montana.edu (2023) ‘Engineering track: Scientific ballooning’, Eclipse Ballooning Project, available: https://eclipse.montana.edu/education/engineeringcourse.html [accessed 18 August 2024].

Polygenis, T. (2023) ‘PETG vs PLA: How do they compare?’ Wevolver, available: https://www.wevolver.com/article/petg-vs-pla-how-do-they-compare [accessed 18 August 2024].

Schwehr, D. (2024) ‘BOREALIS balloon tracking app’, Montana State University, available: http://eclipse.rci.montana.edu/php/prevData.php?fltDate=2023-7-25&imei=300234065065560 [accessed 18 August 2024].

Time and Date (2024) ‘Climate & weather averages in Fort Wayne, Indiana, USA’, available: https://www.timeanddate.com/eclipse/in/usa/fort-wayne?iso=20240408 [accessed 18 August 2024].

Time and Date (2024), ‘Climate & weather averages in Winnemucca, Nevada, USA’, available: https://www.timeanddate.com/eclipse/in/@11788493?iso=20231014 [accessed 18 August 2024].